COPPER LUGS

Copper lugs are electrical connectors used to terminate electrical cables to various electrical equipment, such as switches, circuit breakers, or busbars. They are typically made of high-conductivity copper to ensure efficient electrical connections.

These lugs are usually constructed with a hole or stud for attaching the cable, and they come in various sizes to accommodate different wire gauges. They are often crimped or soldered onto the end of a wire to create a secure and reliable connection.

Copper lugs are commonly used in electrical systems where a high degree of conductivity and durability is required, such as in industrial machinery, power distribution systems, automotive applications, and renewable energy installations. They play a crucial role in ensuring the safe and efficient transmission of electrical power.

Use of Copper Lugs:

Copper lugs are essential components in electrical systems, primarily used for connecting electrical cables or wires to other components like switches, breakers, or terminals. Here are some common uses of copper lugs :

- Power Distribution :In power distribution systems, copper lugs are used to connect heavy-duty cables to distribution boards, transformers, or busbars. These connections ensure efficient and reliable transfer of electricity.

- Industrial Applications :Industries often require robust electrical connections to handle high currents. Copper lugs are used in industrial machinery, equipment, and control panels to provide secure connections between cables and electrical components.

- Automotive Sector :Copper lugs find applications in automotive electrical systems for connecting battery cables to starters, alternators, and other power-consuming components. They ensure stable electrical connections in vehicles, which is crucial for proper functioning.

- Renewable Energy Systems :In renewable energy systems like solar or wind power installations, copper lugs are used to connect solar panels, wind turbines, and battery banks to inverters, charge controllers, and grid connections. These connections play a vital role in transferring generated power efficiently.

- Marine and Aerospace :Copper lugs are also used in marine and aerospace applications where corrosion resistance and reliable electrical connections are critical. They are employed in wiring systems for boats, ships, aircraft, and spacecraft.

- Telecommunications :Copper lugs are used in telecommunications infrastructure for grounding and bonding purposes. They provide secure connections between grounding conductors and grounding electrodes to ensure proper electrical safety and signal integrity.

- Residential Wiring :In residential electrical wiring, copper lugs are used for connecting large gauge wires to circuit breakers, grounding rods, and other electrical components in the distribution panel. These connections ensure safe and reliable electricity supply to homes.

Overall, copper lugs play a crucial role in various sectors where secure and efficient electrical connections are essential. Their high conductivity, corrosion resistance, and durability make them preferred choices for demanding electrical applications.

Advantages of Copper Lugs :

Copper lugs offer several advantages in electrical and industrial applications :

- Excellent Conductivity : Copper is an excellent conductor of electricity, offering low resistance to the flow of electrical current. This property ensures minimal power loss and efficient transmission of electricity.

- Corrosion Resistance : Copper has natural corrosion resistance, making copper lugs durable and suitable for use in various environments, including outdoor and marine applications.

- High Temperature Tolerance : Copper lugs can withstand high temperatures without compromising their structural integrity or conductivity. This property is crucial in electrical systems where heat generation is inevitable.

- Malleability and Ductility : Copper is highly malleable and ductile, allowing for easy fabrication and installation of copper lugs. They can be easily shaped and bent to fit specific applications without the risk of cracking or breaking.

- Compatibility : Copper lugs are compatible with a wide range of wire sizes and types, offering versatility in electrical installations. They can accommodate different gauges of copper or aluminum wires, providing flexibility in design and implementation.

- Low Maintenance : Due to their corrosion resistance and durable nature, copper lugs require minimal maintenance over their lifespan, reducing downtime and maintenance costs in industrial and electrical systems.

- Safety : Copper lugs provide a secure and reliable connection between electrical conductors, minimizing the risk of overheating, arcing, or electrical faults. Properly installed copper lugs ensure safe operation of electrical systems and reduce the likelihood of accidents or failures.

- Environmental Benefits : Copper is a highly recyclable material, making copper lugs an environmentally friendly choice. Recycling copper helps conserve natural resources and reduces the environmental impact associated with mining and production processes.

The combination of excellent conductivity, durability, versatility, and safety makes copper lugs a preferred choice in various electrical and industrial applications.

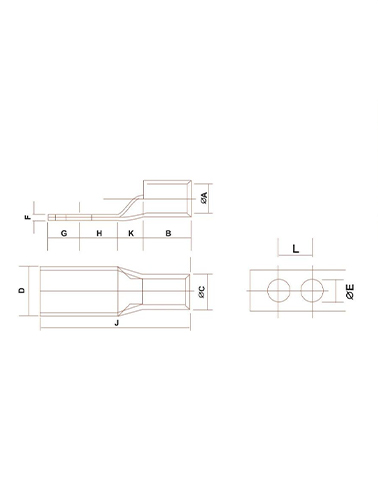

Copper 2 Hole Extended Palm Cable Lugs :

| Size | Multisize |

| Type | Crimped type tinned |

| Material | Electrolytic Copper |

| Application | Cable Use |

| Finishing | Electro Tinned |

45 Degree Angle Copper Lugs :

| Size | All Sizes |

| Type | Copper Lugs |

| Material | Copper |

| Application | Electrical Use, Wire Fittings |

| Color | Brown-pink |

| Feature | Non-Breakable |

| Country of Origin | India |

90 Degree Angle Copper Lugs :

| Size | All Sizes |

| Type | Copper Lugs |

| Material | Copper |

| Application | Electrical Use, Wire Fittings |

| Color | Brown-pink |

| Feature | Non-Breakable |

| Finishing | Coated |

| Country of Origin | India |

Cable Tongue Lugs :

| Size | All Sizes |

| Type | Cable Lugs |

| Material | Copper |

| Application | Cable Use |

| Color | Brown |

| Feature | Non Breakable |

| Finishing | Coated |

| Country of Origin | India |